Industrial Coffee Grinder: Essential for Cafés and Cafés

Industrial Coffee Grinder: Essential for Cafés and Cafés

Blog Article

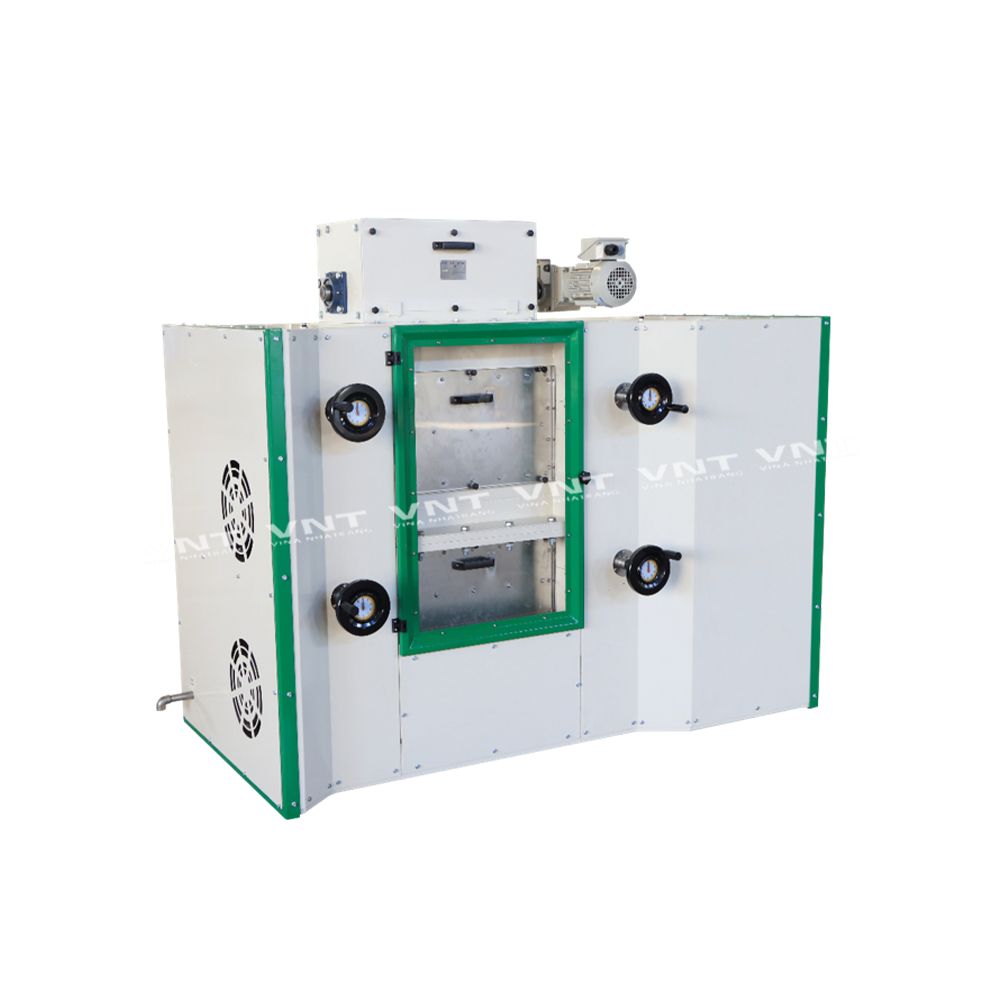

Industrial Coffee Mill Guide: Increase Effectiveness and Top Quality

In the affordable landscape of coffee manufacturing, selecting the ideal industrial coffee mill plays a critical duty in enhancing both effectiveness and product top quality. Understanding the subtleties of numerous mill types and key features-- such as personalized grind settings and durable building and construction-- can dramatically influence the final taste account of the coffee. Furthermore, the optimization of the grinding procedure, paired with persistent upkeep, is crucial for sustaining performance gradually. As we explore these essential elements, it ends up being obvious that the effects prolong past plain equipment choice, impacting total organization success in manner ins which necessitate closer examination.

Recognizing Mill Kinds

When choosing an industrial coffee grinder, comprehending the various types available is crucial for enhancing both flavor extraction and operational performance. The two key sorts of mills are blade grinders and burr grinders. Blade grinders make use of sharp blades that slice coffee beans into inconsistent sizes, bring about unequal extraction and possibly unfavorable tastes. While blade mills are commonly a lot more ideal and budget friendly for small operations, they are typically not suggested for industrial usage.

Inevitably, selecting the ideal type of mill is important to maintaining high quality and efficiency in coffee manufacturing, making it vital for companies to purchase top notch burr mills for ideal results.

Secret Functions to Think About

Selecting a commercial coffee mill requires cautious consideration of numerous key attributes that can considerably affect both efficiency and the overall coffee experience. One of the main elements to review is the grinding system. Burr grinders are generally chosen over blade mills, as they provide a consistent grind dimension, which is essential for optimum removal and taste.

Another important function is the mill's ability. Depending on the volume of coffee you need to process, choose a design that can manage your demands without giving up rate or top quality. Additionally, consider the grind settings offered. A flexible mill with several settings enables you to tailor the grind size to different brewing methods, enhancing the coffee's flavor account.

The building material additionally contributes in longevity and upkeep. Stainless-steel parts typically provide long life and are much easier to clean up, which is important for preserving health standards. Evaluate the mill's sound level, specifically in a hectic café or manufacturing atmosphere, where excessive sound can be disruptive. Investing in a grinder that stabilizes these attributes can significantly enhance both operational performance and the quality of the coffee offered.

Optimizing Grinding Process

To accomplish the ideal lead to coffee preparation, maximizing the grinding procedure is necessary. The work dimension substantially influences extraction, taste, and general quality of the brewed coffee. Different developing methods call for details work sizes; for example, espresso demands a great grind, while French press demands a rugged texture. Understanding the partnership between work useful source dimension and brewing method is the very first step in optimization.

Additionally, keeping an eye on the grinding rate can enhance the procedure. Slower grinding often generates less heat, preserving delicate tastes and fragrances. Alternatively, faster grinding may create excessive warmth, adversely impacting the coffee's high quality.

Maintenance and Care Tips

Appropriate maintenance and treatment of commercial coffee grinders are essential for making certain ideal efficiency and longevity. Regular cleansing is the foundation of upkeep; residue accumulation can impact flavor and grinding efficiency. It is advisable to clean up the mill after each usage, cleaning down the exterior and eliminating any type of coffee premises from the burrs.

Additionally, inspect the grinding burrs for deterioration. Plain burrs can compromise work consistency, so they must be changed as necessary. Industrial Coffee Grinder. Regularly adjusting the mill is also important, as this maintains the preferred grind dimension for numerous developing techniques

Lubrication of relocating components should be executed according to the supplier's specs, as this lowers rubbing and extends the life of the equipment. It is important to make use of food-grade lubricating substances to guarantee safety and compliance with health laws.

Finally, maintain the grinder in a stable and completely dry environment to stop rust and deterioration. By sticking to these maintenance and treatment suggestions, drivers can enhance the effectiveness of their industrial coffee mills while guaranteeing premium result and prolonged functional life.

Roi Analysis

Examining the roi (ROI) for industrial coffee mills is crucial for companies looking for to optimize their coffee manufacturing abilities. A thorough ROI evaluation assists determine the monetary feasibility of purchasing premium mills, permitting organizations to evaluate the preliminary expenses versus prospective gains.

Evaluate the purchase price of the mill, including installation and any kind of needed modifications to existing infrastructure. High-performance mills commonly lead to decreased grinding time and increased throughput, which can dramatically enhance productivity.

In addition, think about the impact on item quality. Industrial Coffee Grinder. Superior mills yield a more constant grind dimension, which can improve flavor accounts and client complete satisfaction, ultimately driving sales. By raising the high quality of the end product, companies can warrant higher rates, resulting in enhanced earnings

Final Thought

In recap, an industrial this content coffee mill plays a critical function in boosting both effectiveness and item quality within coffee manufacturing. By picking top quality burr mills equipped with vital attributes such as adjustable work settings and sturdy building, organizations can ensure ideal taste removal. Routine upkeep is vital for sustaining grinder efficiency and making the most of client satisfaction. Ultimately, the calculated financial investment in a reliable grinder contributes dramatically to improved revenue and competition in the coffee sector.

In the affordable landscape of coffee production, about his selecting the right industrial coffee mill plays a pivotal function in enhancing both performance and item high quality. The two key types of mills are blade mills and burr mills. Within the burr grinder classification, there are level burr grinders and cone-shaped burr grinders, each with its benefits. Burr mills are generally favored over blade mills, as they offer a constant grind size, which is important for ideal removal and taste.

In summary, an industrial coffee mill plays a pivotal duty in enhancing both performance and product top quality within coffee production.

Report this page